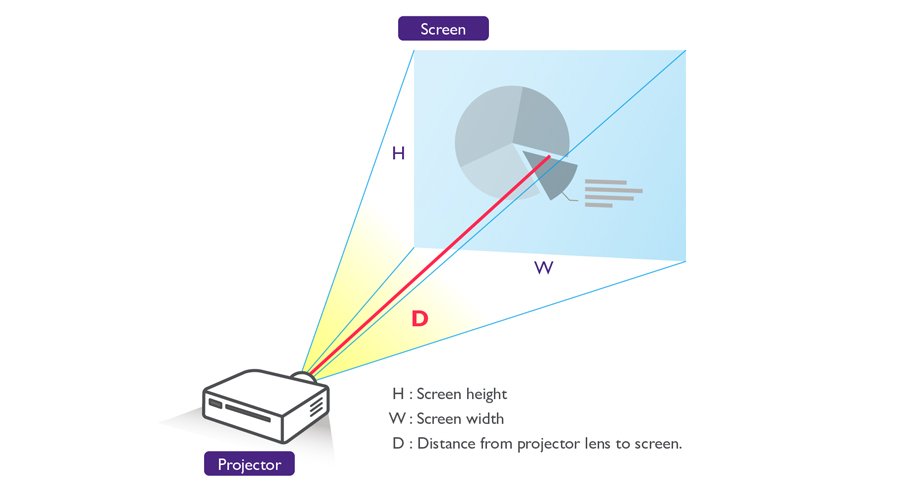

Projector

Explore All Projector Series

By Trending Word

4K UHD (3840×2160) Short Throw 2D, Vertical/Horizontal Keystone LED Laser With Android TV With Low Input LagExplore Commercial Projector

Professional Installation Exhibition & Simulation Small Business & Corporation Education Golf Simulator Wireless Presentation

Monitor

ZOWIE eSports

Golf Simulator

Wireless Presentation